INTRODUCTION

The management of the slurry system in tunnelling projects plays an important part in the safety and efficiency of tunnelling projects. Whether the slurry is used for maintaining face stability or transport of the cuttings to surface, the overall mass balance of solids contained in the slurry going in and out of the tunnel has to be monitored and controlled. Ideally the excavated amount of solids should match the increased density of the discharge flow. If this is not the case, it could be an indication that too much soil is excavated in relation to the theoretical advance rate, which may lead to settlements on surface.

In addition it is important to monitor the density of the recirculated slurry, as part of the fines of the soil particles will not be separated in the separation plant. The density and quality of the feed slurry has to be corrected to maintain the required slurry characteristics.

The monitoring of density and flow rates is achieved by a combination of measuring flow (Q, m3/s) and density of the mixture (ρ, kg/m3). The combination of the two provides the instantaneous production in kg/s.

Measurement of the density is currently done by a radioactive source and a receiver (RA meter). The level of deflection of the radiation is an indicator of the number of particles between source and receiver. Application of this equipment ranges in pipe diameter from 300 mm up to 1000 mm or even more. The method is well-proven in dredging and tunnelling, but has it disadvantages:

• Handling of a radioactive source requires special permits

• Transportation of the equipment must be done with special precautions

• Only certified personnel is authorized to work with the equipment

• Certified personnel has to be present on the site of installation of the equipment

Using technology and extensive experience from the dredging industry, IHC has developed a density meter using harmless radio waves instead of radioactive material as source. This new technology can be used as standard equipment, it requires no special permits and is completely safe.

NON-RADIOACTIVE DENSITY (RF) METER

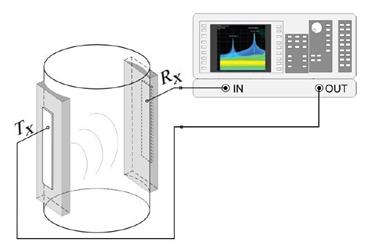

The newly developed density meter uses radio waves to sense the volume concentration of solids present in the carrier fluid. The abbreviation RF stands for Radio Frequency as opposed to RA for Radio Active. The system forms a transmission measurement geometry, where the slurry pipeline is fitted with a pair of antennas. The system performs the measurement by exciting an electromagnetic field, with the transmitting antenna (Tx) and sensing it by the receiving antenna (Rx). The transmission coefficient of electromagnetic wave in the mixture is obtained by an advanced electronic circuit. The microprocessor calculates the amount of solids present in the pipe by relating the measured transmission of the mixture to the transmission of pure carrier fluid.

Principle of operation. A measurement pipe with two antennas is connected to a radio-frequency signal conditioner.

OPERATING PRINCIPLE

The principle of operation requires two openings in the pipe wall. It is realized by two windows, made of polyurethane, well known in dredging industry for its wear resistance. Windows have the same curvature as the pipe wall, resulting in a flush, protrusion-free pipe cross section.

The two main components of the system are the measurement pipe and the signal conditioner. The pipe is a standard spool piece of standard flange size and the length is circa twice the flange diameter. The pipe can be located at any point of the slurry pipeline, with both vertical or horizontal orientations. The only electronic device on the pipe is the radio signal booster, which requires a normal 24V DC power supply.

The signal conditioner, performs signal processing and computation of the density. It is a robust, marine-grade piece of equipment with proven record on hundreds of dredging vessels.

It contains all the input and output interfaces required by process control environment. Specially the analogue, serial and industrial Ethernet interfaces can be used to facilitate with any automation or data collection system.

The embodiment and functionality of the new system is compatible with a standard radioactive measurement pipe.

The outside and inside of the measurement pipe. Two

polyurethane windows are visible.

The density system is totally free from ionizing radiation and only uses radio waves. The steel structure of the pipeline provides sufficient screening from any electromagnetic waves. Nowhere else in the system, high-intensity fields, nor high voltages exist. Thus the measurement pipe poses no safety hazards.

FIELD TRIALS

The RF meter was tested on a dredging vessel operating in estuary waters. Both RA and RF meters were integrated in a 500 mm measurement pipe. Field test showed that the RF meter delivers the same performance and functionality as the RA meter. Laboratory tests also indicated that the use of bentonite has no adverse effects on the accuracy of the measurement. The only limiting factor is the salinity of the fluid. Further research is carried out to overcome this problem. However, in most tunnelling applications, salinity levels can be neglected as long as the bentonite slurry penetrates the soil and fully replaces the groundwater in the mixing chamber of the TBM.

Overall the easy handling of the RF meter can prove to be a significant improvement to contractors in the management of their tunnelling slurry systems.

For further information please click here - www.royalihc.com/tunnelling - or email tunnelling@royalihc.com

Authors:

Hans Greve – IHC Tunnelling, The Netherlands

Jacco Osnabrugge – IHC Systems, The Netherlands