CBE Group recently delivered several segment moulds and a

carousel to the city of Chengdu, in the Sichuan province, for an innovative

technical gallery project.

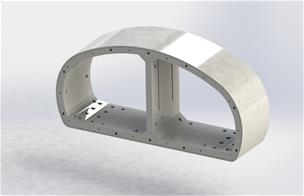

The project’s technical gallery is divided into several

segments, easy to manipulate and endowed with a resilient structure. Usually

built outdoors and equipped with huge concrete panels that are difficult to

manipulate, these galleries are usually not fit for an automated production.

The innovation that CBE Group offers here allows a standardization of their

production, which might catch the interest of several other cities wanting to

simplify the creation process of such projects.

Initially ordered by the Financial Board for Public Works of

Chengdu, associated with Railway Group n°23, the plans for the moulds and

carousel were designed by CBE Group’s Design Office in Saint-Avertin, France.

While the carousel remains fairly standard (aside from a small adaptation on

the concreting station), moulds had to be adjusted, largely due to the oval shape

of the gallery. Out of the 1068 meters of the gallery, 768 meters were created

with precast segments. The remaining part was done in concrete, poured onsite.

The rings which compose the main part of the gallery and were produced using

CBE Group technology are each divided into 5 segments.

This project is composed of two tunnels, each one also

divided in two parts: the first one allows sewage flow on one side and the

installation of cables on the other side. A second tunnel, built on the same

model, shares both water supply and electric cables.

It is the first time that such a project is realized using

precast segments. This first attempt was highly successful: time gain, easier

handling of the pieces and improved resilience of the tunnel are part of the

advantages that make this gallery project a real innovation in the underground

industry.

CBE Group is an French industrial SME, specialized in the

engineering and the manufacturing of steel moulds, precast factories and

maintenance equipment to manufacture concrete segments for all sorts of

tunnels. The company masters every step of the process: from the conception in

the Design Office to the launch of the plant.

Created in 1987, CBE was bought in 2005 by Didier Lefebvre,

who launched CBE Group. On October 3rd, 2017, Philippe Samama became the new

CEO after a change in capital within the company. Located in the Loire Valley

region, its main offices are in Saint-Avertin (37), with two production sites

in L’Ile Bouchard, France and in Yangling, China.

CBE Group / 1987-2017 • 182 carousels • 23 570 moulds

produced • 500 projects in 52 countries • 250 employees in France and in China

• APS – Advanced Precast Systems CBE Group has tried to diversify its offer in

order to reach new markets in the precast world, offering to manufacture moulds

for any type of concrete element (railway sleepers, noise barriers,

breakwaters) using industrial methods. Its dedicated department, Advanced

Precast Systems (APS), launched in 2014 the first ever automated plant for the

production of artificial blocks for breakwaters in La Réunion. Other similar

projects have been launched since in France and abroad. www.aps.cbegroup.fr • ACIMEX In 2010, CBE Group purchased

ACIMEX, leader in the domain of industrial gripping and lifting of heavy loads

and pieces. ACIMEX designs and manufactures vacuum devices for the handling of

concrete, steel or PVC pieces and large scale tubes and pipes, using vacuum technology

or hydraulic clamps. These systems are able to lift and handle up to 30 tons in

full safety.