The Award-winning E-Power Pipe® system, which was developed

by Herrenknecht AG as a new method for the quick and secure installation of

small-diameter cable protection pipes underground for drive lengths of over a

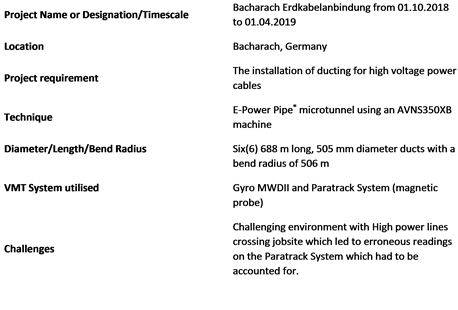

kilometre, was recently employed to complete a project in Bacharach, Germany.

The works comprised the boring of six (6) 688 m long, 505 mm

diameter ducts for the installation of high voltage power cables as part of the

Bacharach Erdkabelanbindung project. The installation was complicated by the

fact that the routes of all six ducts was required to include a 506 m radius

curve.

The E-Power Pipe® system is a small diameter microtunnelling arrangement

that in this instance utilised a Herrenknecht AVNS350XB microtunneller. The

challenge for the project was that, with the combination of the included curve

and the long distance, guidance for the small diameter microtunneller was a

challenge.

To overcome this, the contractor called on tunnel navigation

specialist VMT’s expertise to design a special guidance system to provide the

necessary accuracy for the bores. The system developed utilised two proven

techniques which included both a Gyro MWDII and a Paratrack 2 System (magnetic

probe).

VMT’s challenge was to provide a guidance system that would

not only ensure accuracy of the individual bores but also handle the

challenging environment which included high voltage power lines which crossed

the site which, as the project proceeded, led to erroneous readings with the

Paratrack 2 System.

The project was something of a pilot project in that the

systems had not been used like this in combination before. However it was

decided that the comparison of the sensor data from both navigation devices

would provide sufficient data to show if the navigation system could be

trusted. Manual measurements with a TCA showed that the vast majority of the

data from the magnetic probe was very useable. Where any minor discrepancies from

the magnetic probe did occur this could be adjusted for by using the data from

the gyro, so at no time was there any potential for the microtunneller to

operate without confidence in the steering.

The fact that the personnel involved had no experience of

such a system did not deter VMT’s staff and with a lot of new enhancements to

VMT’s guidance software prior to the project a system was developed that it was

believed would provide the accuracy required.

Ultimately on the successful completion of the bores the VMT

system utilised by the E-Power Pipe® system proved to be a very suitable

guidance solution for TBMs without a line of sight available and where no

conventional control measurements were possible as all drives reached their

target.

According to the VMT crew onsite for the works: “We learned

a lot about the system during the advance and were able to gradually reduce the

service on site and transfer more automation in the process as the project was

ongoing.”

At a Glance Fact Sheet:

For further information please visit https://vmt-gmbh.de/blog/combining-guidance-technologies-provides-accurate-solution-for-cable-installation

or contact VMT by clicking this link https://vmt-gmbh.de/en/contact/