Dramix steel fibre concrete reinforcement

Bekaert is a worldwide group with over 150 production centres, with the combined sales of over €3.2 billion, and a workforce of 18500 It is the leading independent producer of high-grade steel cord, steel wire, and advanced materials. The company's market and technological leadership is based on metal forming and a wide range of coating technologies for our customers in 120 countries in all industrial sectors.

Bekaert has manufactured the range of Dramix® cold drawn wire steel fibres for over 30 years which, when added to concrete provides an homogeneous reinforcement for many applications in the construction and civil engineering industry.

Dramix® steel fibre-reinforced concrete is used in many tunnel applications and with sprayed concrete this has the advantage of quick and safe application, uniform thickness and strong bond, and is both cost-effective and safe to use. The fibres are available in different performance classes with different l/d ratios according to the performance requirements, the application and the equipment used. Dramix® can be used with traditional additives, but trials are always advised. Dramix® fibres are glued together in bundles using water-soluble glue. The bundles separate easily into single fibres and guarantee a homogeneous distribution in the concrete mix. The shape and type of fibre design took five years to develop, and has stood the test of time for all these years. Research and experience has created an optimal balance between shape, tensile strength, length and diameter. Carefully designed hooked ends are provided for optimal anchorage in the concrete. Dramix complies with the relevant national and international standards such as ASTM, JSCE and the Euro codes.

When Dramix® steel fibre-reinforced sprayed concrete is used for tunnel inner linings, savings are made from the elimination of manufacturing, transport, handling and positioning of conventional reinforcement. Benefits also accrue from reduced sprayed concrete consumption, less rebound, increased load-bearing characteristics, and better bond, other benefits include inhibition of spalling and reduction in crack widths, thus enhancing the sealing capability of the lining. These properties are also important in sprayed concrete used for slope stabilisation around tunnel portals and other works such as spraying on to pile walls in basements.

When Dramix® steel fibre-reinforced sprayed concrete is used for tunnel inner linings, savings are made from the elimination of manufacturing, transport, handling and positioning of conventional reinforcement. Benefits also accrue from reduced sprayed concrete consumption, less rebound, increased load-bearing characteristics, and better bond, other benefits include inhibition of spalling and reduction in crack widths, thus enhancing the sealing capability of the lining. These properties are also important in sprayed concrete used for slope stabilisation around tunnel portals and other works such as spraying on to pile walls in basements.

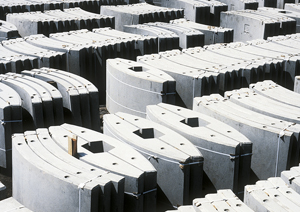

When used in concrete, Dramix® steel fibre reinforcement is active throughout the entire mix. For precast segment manufacture, because there is for example no handling, storage and positioning of steel reinforcement cages, the production cycle time is reduced and productivity is increased. The finished product offers improved impact resistance during handling, erection, and TBM reaction; improved loading capacity; less spalling damage; and enhanced durability. For cast insitu linings, the reinforced wet concrete can be extruded or pumped into the formwork.

In mining applications, steel fibre-reinforced sprayed concrete offers early support and protection from spalling rock, resulting in faster access to profitable ore. It can be used as primary support for short-life applications, and as a final lining for permanent openings and the control of the crack width reduced the potential for water penetration into working areas.

In mining applications, steel fibre-reinforced sprayed concrete offers early support and protection from spalling rock, resulting in faster access to profitable ore. It can be used as primary support for short-life applications, and as a final lining for permanent openings and the control of the crack width reduced the potential for water penetration into working areas.

Bekaert operates worldwide, and provides expert advice on lining design and installation to its customers. It has been involved in a great many major infrastructure tunnelling projects, and can rightly claim to be one of the foremost innovators in the steel fibre reinforcement industry, its products and original inventions being widely emulated. The company published many years ago an excellent 230 page illustrated reference text entitled "Tunnelling the World" that described many developments in sprayed concrete technology and equipment with particular reference to steel fibre concrete reinforcement this has now been followed up with the publication in late 2006 of a 400 page edition of “Tunnelling is an Art” .

tel +32 56 766986, fax +32 56 767947, or visit www.bekaert.com/building

© tunnelbuilder ltd