|

In the globally operating speciality-chemicals group Sika AG, with its headquarters in Switzerland, business in the field of underground construction is concentrated in the hands of Sika Tunneling & Mining. Here new developments in the three core competence fields Construction Chemicals, Equipment and Waterproofing Systems are pushed and offered to the market by the world-wide net of Sika Companies being reliable partners for our customers. The recently launched world-wide alliance with the concrete pump experts Putzmeister has caught on last year and today, the concrete spraying system Sika-PM500 is the top-of-the-range system for high-performance shotcreting. Further systems, amongst others also for mining, are coming up shortly. Manufacturing of special TBM mounted shotcreting robots represents a further prosperous foothold in the market. Today such systems prove successful all over the world. In the field of shotcrete and concrete admixtures Sika has successfully strengthened its leading position with the latest Sika ViscoCrete generation, suitable also in precast element production. For meeting the very particular requirements in tunnel construction, such as for the world-longest railway tunnel AlpTransit Gotthard, Sika ViscoCrete allowed developing specific solutions with our customers. Since decades Sika waterproofing systems perform reliably all over the world. Substantial waterproofing work carried out in the two base tunnels Lötschberg and Gotthard represents a further milestone for the use of SikaPlan products and systems. Sika Tunneling & Mining stands for practical solutions in underground construction, today and tomorrow. |

||||

|

||||

|

|

|

Sika's comprehensive consulting services ensure technically appropriate and economically interesting system and product solutions for all types of problems encountered in underground construction. Equipment |

|

|

For shotcreting by thin stream method (compressed air stream), the product range starts with the Rotor machine ALIVA® -246. This compact Rotor machine is particularly suitable for working in restricted space conditions. Its output capacity is up to 4 cu m/h in dry process spraying. General requirements such as sand blasting, repair work, concrete spraying can be satisfied by conversion of the spraying equipment. Such versatility is made possible by the continuously variable output. The customer can opt for an electric or a pneumatic driving unit. The bigger ALIVA® -252 offers double output capacity. It is designed to be used in mines, galleries and for slope stabilization, to mention only a few of possible uses for the ALIVA® -252. |

||

|

The next two Rotor machines ALIVA® -263 and ALIVA® -285 are also called Duplo, which means that they can be used for spraying dry mixes as well as wet mixes. Maximum output capacity of the ALIVA® -263 is 15 cu m/h and the ALIVA® -285 reaches 19 cu m/h. Both Rotor machines achieve maximum 300 metres conveying distance. The outstanding characteristic of all Rotor machines is pulsation-free spraying. Sika® -PM702 is used for dense stream shotcreting. This twin-piston concrete pump can reach 20 cu m/h output at 70 bar concrete pressure. Thanks to its practically pulsation-free pumping, this machine is perfectly suitable for the spraying of concrete. Dosing unit for liquids Mini Shotcreting System ALIVA

Ò -503 |

|||

A container with 200 litres capacity for admixtures can additionally be mounted onto the vehicle. |

|

||

The Sika® -PM500 performs reliably and achieves high-quality results thanks to its components. The shotcreting system consists of the following main components: Spraying boom SA13.9 inclusive of mobile nozzle mount, liquid-dosage unit ALIVA® -403.5, concrete pump BSA 1005 or Rotor machine ALIVA® -285 and control unit. These components are mounted onto a 4x4 vehicle from Lorenzana Company. Compressor and wireless remote control are available as options. The twice telescoping spraying boom SA13.9 is very sturdy. The spraying height of 19 metres allows the use of the system also in large tunnels. Thanks to the wide working range, loss of time caused by shifting of the system is reduced to a minimum. The customer can choose between the concrete pump BSA 1005 or the Rotor machine ALIVA® -285. The longitudinally mounted long-stroke pump BSA1005 is suitable for maximum spraying performance of up to 30 cu m/h and assures optimal concrete quality and finish. All these features go together with a long service life. |

|||

|

The Rotor machine ALIVA®

-285 is mounted onto a hydraulic lifting platform which allows lowering

the filling hopper to a user-friendly level. All control elements for the functions of the spraying system are centrally, clearly and practically disposed on the control unit outside the manoeuvring space. The Sika® -PM500 has successfully passed its crucial test. All systems have perfectly proven themselves in the tough environment of tunneling sites. |

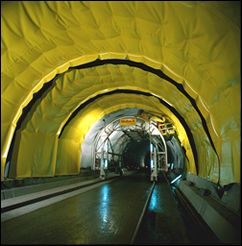

Safe operation - in particular under traffic - as well as durability and the problemless functioning of all technical installations inside the underground structure are top priority. |

||||

| Electrification of the Gotthard railway line

with all its tunnels at the biginning of last century was for Sika the occasion

to lay the foundation for tunnel waterproofing. Today the specialists consider

waterproofing of underground transport infrastructure to be indispensable.

With the quick-setting cement mortar Sika marked the beginning of the first

tunnel waterproofing age and has since then never ceased to play a decisive

and competent part in developing new waterproofing technologies. The installation-friendly Sikaplan PVC and the high-flexibility Sikaplan FPO tunnel waterproofing membranes are state-of-the-art and enjoy a high standing in the market. Sika Tunneling & Mining offers a comprehensive product range, including injectable waterstops and various special parts, and is therefore your competent partner for all waterproofing problems in tunnelling. |

|

|

Our innovative problem solutions offered by the 'Waterproofingsystem'-Team will also keep your underground structure durably waterproof. For further information: © tunnelbuilder ltd |

|